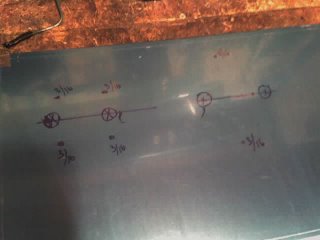

The headphone trick helped determine where to place the power and output transformer. Marking the mounting holes, it is time to drill. The small (3/16") holes are for mounting the transformers. The larger holes will be used to feed the primary and secondary wires through the chassis. I forgot to order grommets with my order - but this is something that should be found at the hardware store. I like the harware selection at Woodruff-Arnold, which is also where I buy the nuts, bolts, and various parts that make everything fasten together. A guy came to ask if I needed help, and I asked him if they carried rubber grommets. He didn't even think about it, he just said "no." About 30 seconds later, I was standing in the electrical hardware aisle right in front of a drawer that said "Grommets - Rubber." People.

The headphone trick helped determine where to place the power and output transformer. Marking the mounting holes, it is time to drill. The small (3/16") holes are for mounting the transformers. The larger holes will be used to feed the primary and secondary wires through the chassis. I forgot to order grommets with my order - but this is something that should be found at the hardware store. I like the harware selection at Woodruff-Arnold, which is also where I buy the nuts, bolts, and various parts that make everything fasten together. A guy came to ask if I needed help, and I asked him if they carried rubber grommets. He didn't even think about it, he just said "no." About 30 seconds later, I was standing in the electrical hardware aisle right in front of a drawer that said "Grommets - Rubber." People. Drilling stuff like this screams for a stepper bit. Irwin sells one called "Unibit," but I ended up buying one from Greenlee. Actually, it came from Lowes. This one drills very neat holes from 3/16" to 7/8" in 1/16" steps. When drilling metal, be sure to clamp it down! For the big holes (like for the vacuum tubes), I spray WD-40 to keep the bit and the metal cool.

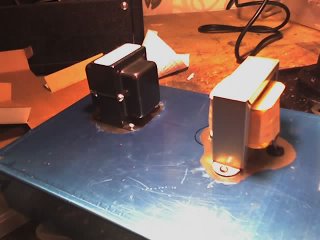

Drilling stuff like this screams for a stepper bit. Irwin sells one called "Unibit," but I ended up buying one from Greenlee. Actually, it came from Lowes. This one drills very neat holes from 3/16" to 7/8" in 1/16" steps. When drilling metal, be sure to clamp it down! For the big holes (like for the vacuum tubes), I spray WD-40 to keep the bit and the metal cool. In case you are curious, the chassis is made of aluminum. This makes drilling very easy. The chassis will be mounted upside down, and if I was dealing with a larger amp aluminum might not work so well. The higher the output, the larger the transformers. The cooling black transformer is the power tranny. The ugly-ish one in the middle is the output transformer. They are both from Hammond.

In case you are curious, the chassis is made of aluminum. This makes drilling very easy. The chassis will be mounted upside down, and if I was dealing with a larger amp aluminum might not work so well. The higher the output, the larger the transformers. The cooling black transformer is the power tranny. The ugly-ish one in the middle is the output transformer. They are both from Hammond.--gh

3 comments:

I think oil - plain old motor oil - is better for drilling...

...maybe for steel. Aluminum is all weird and stuff. The lubricant that I would prefer to use is kerosene, actually. But I don't have any around, and I didn't care to buy a gallon of it for $8 since this is my only use of kerosene.

Maybe I should buy a gallon and keep a small amount in a tin and give the rest to the rock saw lab. Kerosene is also used to lubricate during the cutting of rocks.

I find that regular motor oil cooks too fast and gets discolored. Smokes at a lower temperature, too. But maybe that is a good thing - if it smokes at all, it's getting too hot.

--gh

I only use synthetic blend motor oil. I bet it would hold up better than regular o'l.

Post a Comment