I mentioned

last time that I needed to design and paint the chassis of the amp first. Unless you don't mind junk, amp building

really needs to be planned, designed, and layed out with good preparation.

Here is a picture of what the amp chassis looks like:

In case you are wondering, I paid an

amp parts service to punch and drill the chassis. If this one works out well, then my next tool will be a drill press and I will do that on my own.

I did settle on calling this first amp build "Mr. French," which comes from the 60s TV show

Family Affair. Here you can see that I simplified a layout template and cut out critical areas with an X-acto knife.

Some of my Geo-Tech students may recognize how I will layout the front plate. Instead of Mylar, I will draft directly onto the front of the chassis. I had a huge block of oak leftover from a previous project, and I just clamped the chassis on at the same level. (Sorry for the picture quality. My motorola phone only has VGA-quality pictures, and no flash. Some day I will get a digital camera.)

I really took a chance that this would work. I primed the chassis, and then painted it with a flat white. My hope was that I could draw with rapidograph pens directly onto the chassis with India ink. This is water soluble, so I can have a little play while I am working on it. Water soluble means that once the water leaves, there is nothing but dry ink (with a healthy dose of clay in India ink), which means that I should be able to clearcoat it afterwards. Here is the beginning of the layout. Check out the Leroy lettering system!

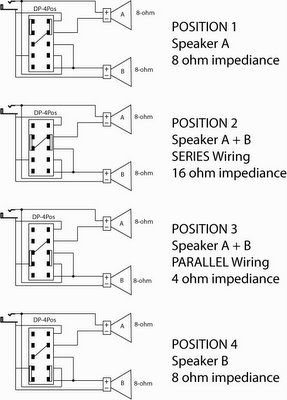

This is starting to look like I know what I am doing. Here is the back of the amp. It is very critical to have the speaker output labeled, so I wasn't just being fancy here. If you don't plug a speaker into a tube amp like this, you will fry your output transformer, and probably the tube as well. Mismatching impedances could be just about as bad. (For a visual image, imagine placing your screw driver right across the car battery - the battery wants a load and does not want to just short out to nothing like that.)

I am finished with the faceplate layout. I am impressed with how this will work (assuming the clearcoat doesn't mess things up). A lot of amp builders struggle with the face plate - sometimes paying $50 for someone to laser cut a decent design. This won't look as nice as that, but it only cost time (about an hour) and about three cents of ink.

Faceplate:

Mr. French closeup:

Input (blacklinefish name) closeup:

Issues - you may notice that the layout of the numbers is not perfect. I also hope that they are centered okay when the knobs are installed. Also, the "t" in the phrase 'The Gen

tleman's Gentleman" is darker - that was me trying to touch up something I already lettered by hand. It usually doesn't work so I wish I had left it alone.

I wrote "STANDBY" above the switch because the words for "MR. FRENCH" got in the way! Also, the reason I wrote "POWER-off" like that is because I only wanted to use the word "POWER" but I got lazy with the layout and it was no centered well under the hole for the switch. I did not feel like erasing the word because that would have taken 45 seconds or something. So, it permanently has this distinctive layout. (The hole on the farthest right is a lamp, in case you are wondering why it is not labeled.)

--gh

P.S. Here's the funniest thing so far. All those years of manual cartography and cadastral mapping really paid off with making this look more than amateur. But I haven't spent too much time with a can of spray paint. (No, I did not spend my youth tagging.) So, the clearcoat went on really nice, and all of the lettering really darkened up nicely. However, I was a little heavy on the first coat, and it may be a little drippy looking. Still, I think it will work out fine.