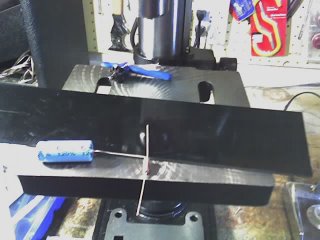

I was at the hardware store the other day picking up the wood for the cabinet. I can't remember why, but I wanted to have the cabinet assembled before finishing the chassis and painting it. Maybe I will remember why. Anyhow, I was set on pine again, but this is a gift. So, I spent twice as much and bought a length of poplar. Here you can see a bit of my workshop in the basement. It's nice to not have to do this type of stuff in the garage. It's still a bit chilly in the winter, though. My workroom is a small room that was formerly storage space for coal. I even have a coal door which is nice for bringing long things in and out of there. Yeah, coal... my house is old.

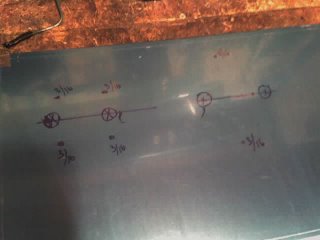

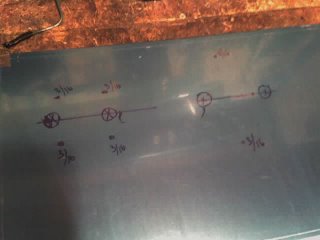

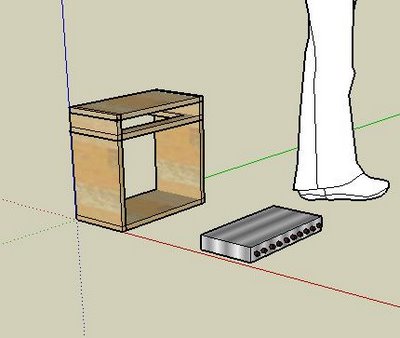

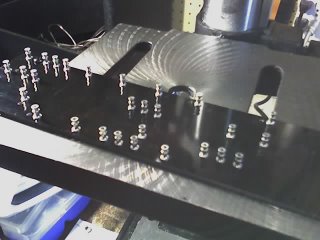

I was at the hardware store the other day picking up the wood for the cabinet. I can't remember why, but I wanted to have the cabinet assembled before finishing the chassis and painting it. Maybe I will remember why. Anyhow, I was set on pine again, but this is a gift. So, I spent twice as much and bought a length of poplar. Here you can see a bit of my workshop in the basement. It's nice to not have to do this type of stuff in the garage. It's still a bit chilly in the winter, though. My workroom is a small room that was formerly storage space for coal. I even have a coal door which is nice for bringing long things in and out of there. Yeah, coal... my house is old. The poplar is 1x12, even though it will end up a little over 9 inches wide. I will rip these after I cut the dovetails. Right now I can't make the dovetail joint work by measuring first. The edges are off anywhere from a 1/16th to 1/8th inch. So, I will route the dovetail, mark the real edge, and then rip the final piece. This will leave a box shape 2-3 inches deep that has dovetail joints - I won't discard them. I think I will make some trays or something out of them. This is hard to describe without a picture. This room is right next to my workroom. It is just empty space in the basement next to the water heater and furnace. Our basement isn't filled with books or boxes or whatever. We are not packrats.

The poplar is 1x12, even though it will end up a little over 9 inches wide. I will rip these after I cut the dovetails. Right now I can't make the dovetail joint work by measuring first. The edges are off anywhere from a 1/16th to 1/8th inch. So, I will route the dovetail, mark the real edge, and then rip the final piece. This will leave a box shape 2-3 inches deep that has dovetail joints - I won't discard them. I think I will make some trays or something out of them. This is hard to describe without a picture. This room is right next to my workroom. It is just empty space in the basement next to the water heater and furnace. Our basement isn't filled with books or boxes or whatever. We are not packrats. There is something very satisfying about having this project come from one single 8-foot board. Only 11 inches was left, which is why I went up in quality for the wood. Since it was only one board, it wasn't going to break the bank. I don't even know what poplar looks like as a finished product, maybe I should look into that and stuff. This is really going to be a step up from my first project. I am going to take this slow and do it right.

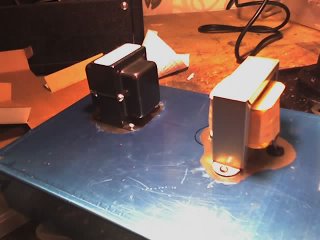

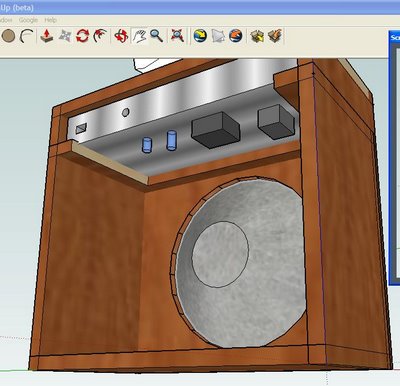

There is something very satisfying about having this project come from one single 8-foot board. Only 11 inches was left, which is why I went up in quality for the wood. Since it was only one board, it wasn't going to break the bank. I don't even know what poplar looks like as a finished product, maybe I should look into that and stuff. This is really going to be a step up from my first project. I am going to take this slow and do it right.I even got some grille cloth for the speaker this time. There are several ways to do that, and I haven't made my mind up. I think I will permanently mount the speaker baffle to make the cabinet stiffer and stronger. I plan to use no fasteners whatsoever on the main cabinet. It will be glue only, and of course the dovetails. Integrating the speaker baffle will make it that much stronger, as well as the shelf for the cabinet. Once glued together, this will take a sledgehammer to take apart again.

--gh